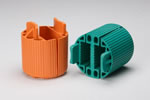

Sonotube® is a registered trademark product of Sonoco Products Company and SPC Resources. Sonotubes® are high quality heavy-duty cardboard structures into which concrete is poured to create a smooth-sided column. The tubes have to be able to withstand the pressure of concrete and have a smooth interior to ensure a flawless column wall finish. Read More…

As a member of the Member of the Independent Converters Association, we know the business of cardboard tubes. Our tubes are some of the strongest in the industry and we can meet a huge variety of needs from many different industries.

Valk Industries provides engineering and manufacturing services for cardboard tubes as well as custom thermoformed items like clamshells, blister packs, trays and filler material.

Western Container partners with the world`s top spiral tube equipment designers & paperboard manufacturers, to bring our customers the very best paper tubing and precision cores.

Chicago Mailing Tube is a premier manufacturer of custom paper tubes, containers, and cores, providing products that are both high quality and economical. CMT has been meeting custom size and design requirements for its customers since 1902.

Here at Paper Tubes and Sales we are a proven manufacturer of high quality cardboard tubes. These products are ideal for a multitude of industries and our teams are available to assist you with determining the best paper tube for your application.

At Wes-Pac Converting, we have made it our mission to ensure that our customers are having their needs and expectations met, and to turn first time customers into lifelong connections. We offer white tubes, kraft tubes, Snap-Loc tubes, telescopic tubes, and more. All of our tubes are 100% recyclable. For more information on how we may be of service, get in touch with our customer service...

More Sonotube® Manufacturers

They are made with spiral wound fiber layers and adhesive bonding, and are extremely strong in cylinder form.

Concrete columns are used in a wide variety of applications, and Sonotube® provides a cost-effective and efficient method of producing a variety of sizes of columns in terms of diameter and length. Short, wide columns are often used as bases for parking lot lamps, streetlights, street signals and deck posts. Tall columns are used for external decoration or roof support around buildings, foundational support in basements and warehouses, and many others.

Other uses have been found for Sonotubes® because of their incredible strength-to-weight ratio and cost-efficiency. Sound technicians and sound hobbyists are using Sonotubes® cut vertically in half to improve the acoustics in auditoriums and sanctuaries. They have also been used to construct sound cabinets as the cardboard walls don't absorb the sound waves and so are an ideal material choice.

The versatility of Sonotube® is one of its many advantages. When fiberglass or steel column supports are used, the number of columns poured is limited to the equipment on hand. Sonotubes® however are disposable and do not need to be reused, they also do not need added exterior support as fiberglass and steel tubes do. Therefore, the overall construction time is drastically reduced as multiple tubes are able to be poured simultaneously. They are also recyclable.

Once the concrete column has set in the paper tube cavity, the outer cardboard layer can be removed and disposed of. They are typically made from biodegradable paper and so depending on the intended use of the column, can be left on or removed whole or in pieces. The tubes are manufactured between 8 to 56 inches in diameter and up to 18 feet long, Sonotubes® offer versatile solutions for almost any concrete project. The pouring of the concrete is fairly straightforward, although for the longer columns, extra machinery may be required to ensure proper placement of the concrete.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

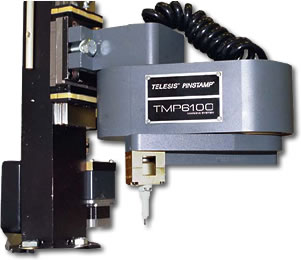

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services