Paper product manufacturers can fabricate cardboard cores in many different sizes and thicknesses. Cardboard cores are manufactured from wood pulp fiber, and these fibers are wrapped around a rod in a spiral to create a tube shape. When discussing the size of the core, one must consider both the core’s diameter and length. Read More…

As a member of the Member of the Independent Converters Association, we know the business of cardboard tubes. Our tubes are some of the strongest in the industry and we can meet a huge variety of needs from many different industries.

Valk Industries provides engineering and manufacturing services for cardboard tubes as well as custom thermoformed items like clamshells, blister packs, trays and filler material.

Western Container partners with the world`s top spiral tube equipment designers & paperboard manufacturers, to bring our customers the very best paper tubing and precision cores.

Chicago Mailing Tube is a premier manufacturer of custom paper tubes, containers, and cores, providing products that are both high quality and economical. CMT has been meeting custom size and design requirements for its customers since 1902.

Here at Paper Tubes and Sales we are a proven manufacturer of high quality cardboard tubes. These products are ideal for a multitude of industries and our teams are available to assist you with determining the best paper tube for your application.

At Wes-Pac Converting, we have made it our mission to ensure that our customers are having their needs and expectations met, and to turn first time customers into lifelong connections. We offer white tubes, kraft tubes, Snap-Loc tubes, telescopic tubes, and more. All of our tubes are 100% recyclable. For more information on how we may be of service, get in touch with our customer service...

More Cardboard Core Manufacturers

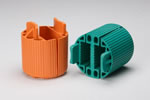

The core’s diameter is determined based on the diameter of the rod around which the cardboard fiber is being wrapped. As more of the fibers are being wrapped, the tube slowly moves along the rod, continuously increasing the length of the rod. Once the desired length is achieved, the tube is cut, and the next tube continues where the severed tube left off. The thickness of the core is determined by the number of layers added to the tube.

Cardboard fibers are typically stored in large rolls, and multiple rolls can be used simultaneously to wrap additional layers as the core is created. The larger the thickness of the core the stronger and more durable it will be. When purchasing cardboard cores, these three features should always be considered in order to find the right core for your applications.

Cardboard cores are particularly useful for storage and retrieval applications. Products that come in sheets are commonly wrapped around cardboard cores. This makes it incredibly simple and efficient to access specific amounts of the product. Many household products utilize paper cores for this purpose. Familiar items include toilet paper, aluminum foil, paper towels, wax paper, and wrapping paper.

Industrial companies use cardboard cores for the same purpose, but they also use them to store and ship finished products. Wrapping products in this way allows the product to make it to the customer in much better condition as it keeps the product from tearing, crinkling, or knotting. While similar cores are made from plastics, cardboard cores are much more affordable and provide a more sustainable option.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

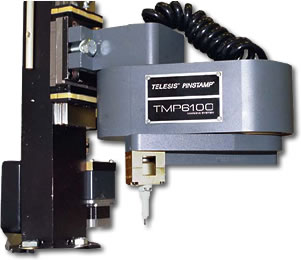

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services